HOME » Vision for the future

|

|

|

-

Global Overseas Expansion

- Japanese domestic automobile sales peaked

in 1990 with 6 million vehicles sold.

In the following 20 years, sales have

tended to either crawl sideways or decline,

and at this point, considering the country’s

declining birthrate, we don’t expect to see

the numbers rise anytime soon. However,

if we turn our attention overseas,

we see a situation different from that of

Japan-countries that are just starting

the process of motorization.

In Delhi, India in 2006, we began our advance

into overseas markets.

Subsidiary BACI has expanded its scale of

business beyond the initial plans,

and is in a position where it can grow

and expand for a long time.

For the future, our primary client,

Suzuki (Inc.), is expected to accelerate

its overseas expansion with a focus on

Southeast Asia.

Our company is moving its global expansion

forward as well, with an eye on our

next production base.

-

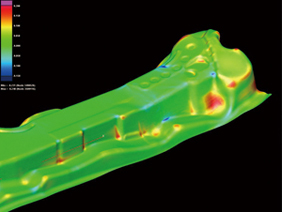

Pursuit of Manufacturing Technology

- Right now, the most sought-after

thing in the automobile industry

is the development of environmentally

friendly vehicles. Energy conservation,

increased gas mileage, lower CO2

emissions and the development of engine

technology towards those ends, as well

as the overall reduction of vehicle

weight are the tasks set before us.

As the top maker of auto body parts,

we are aggressively focusing research

and development efforts on manufacturing

technologies for more light-weight

materials such as titanium, magnesium,

and hyper-tensile steel plating,

and we are making progress with and

obtaining substantial, steady results

from various research collaborations

with the University of Tokyo’s Graduate

School of Engineering, the Toyohashi

University of Technology’s Production

System Engineering Group,

and the Mechanical Engineering Group of

Shizuoka University’s Department of

Engineering.

-

Flexible Production System

- In order to come out on top in the

global competition to get more

serious about emerging countries

and the fluctuations of the customers’

needs and demands, we aim to put

together a Flexible Production

System (FPS), a general production

system that will respond flexibly

and rapidly to all these changes,

and we will work incessantly to reform

and improve it.

-

An Environmentally-Friendly Enterprise

- The 20th century was one of war and

environmental destruction, and the

development of human society had a

negative influence on the environment.

For the 21st century, human kind has

an obligation to put the brakes on

environmental destruction and engender

its rehabilitation. In our company’s

efforts to improve the environments,

we have earned ISO14001 certification

and, via our environmental committee,

we are making progress at reducing

industrial waste, promoting recycling

and reducing CO2 emissions through

promotion of energy conservation.

Moreover, as a maker of auto body parts,

we take it as our mission to make free

use of our technology development

power and aggressively pursue the

manufacture of environmentally

friendly vehicles.